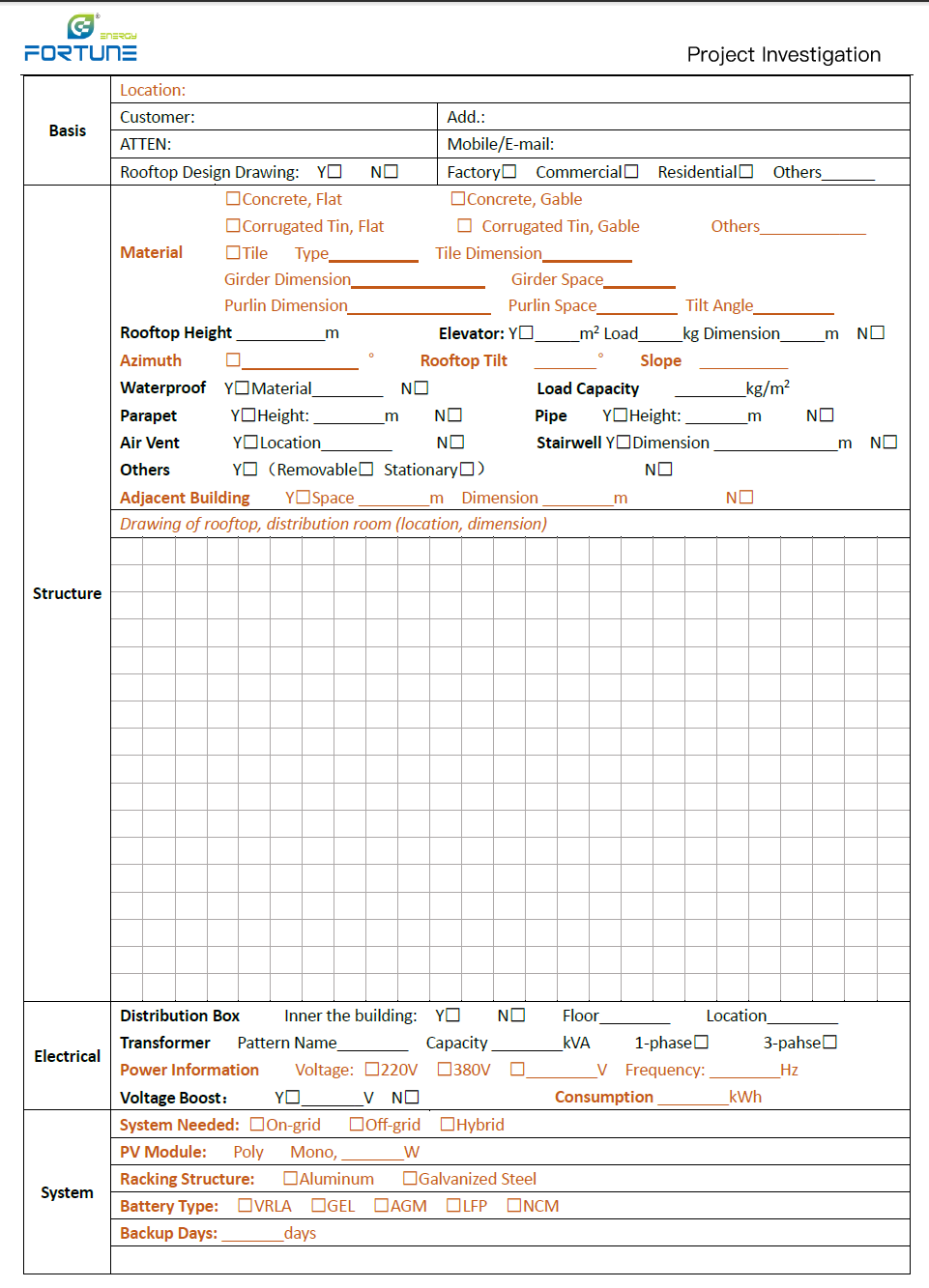

PV PLANT DESIGN

Site Survey Report

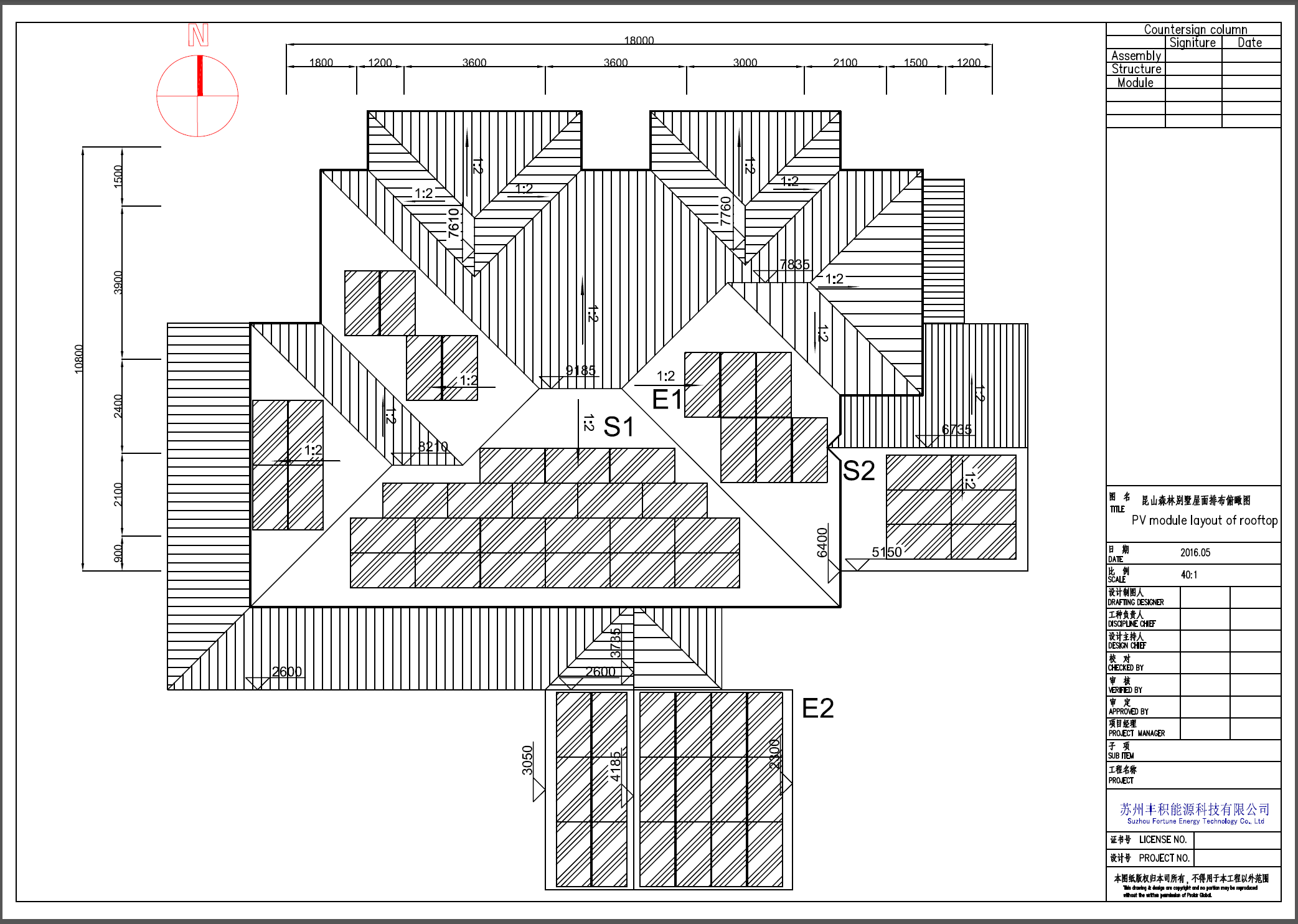

Module Layout Design Drawing

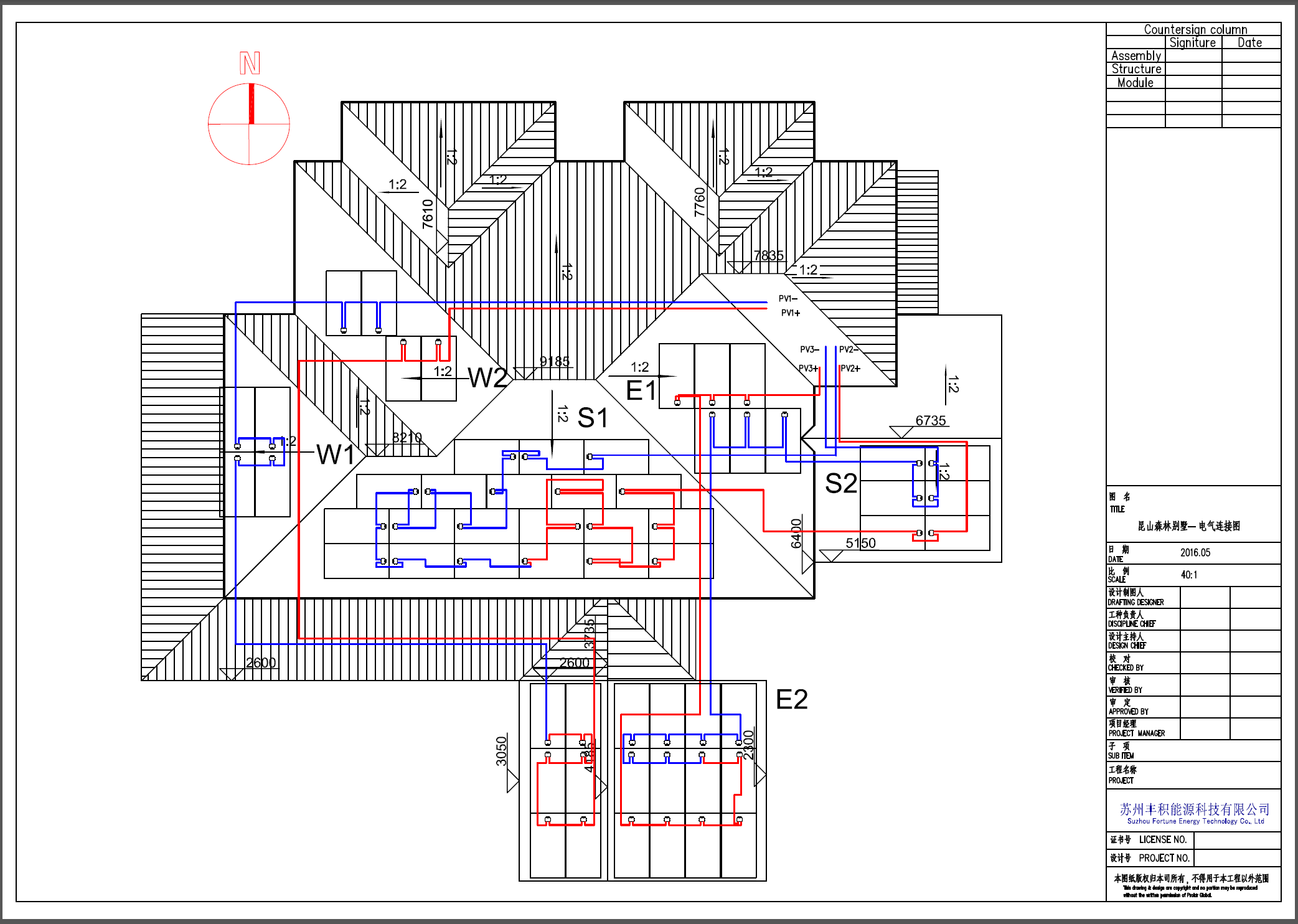

Electrical Connection Design Drawing

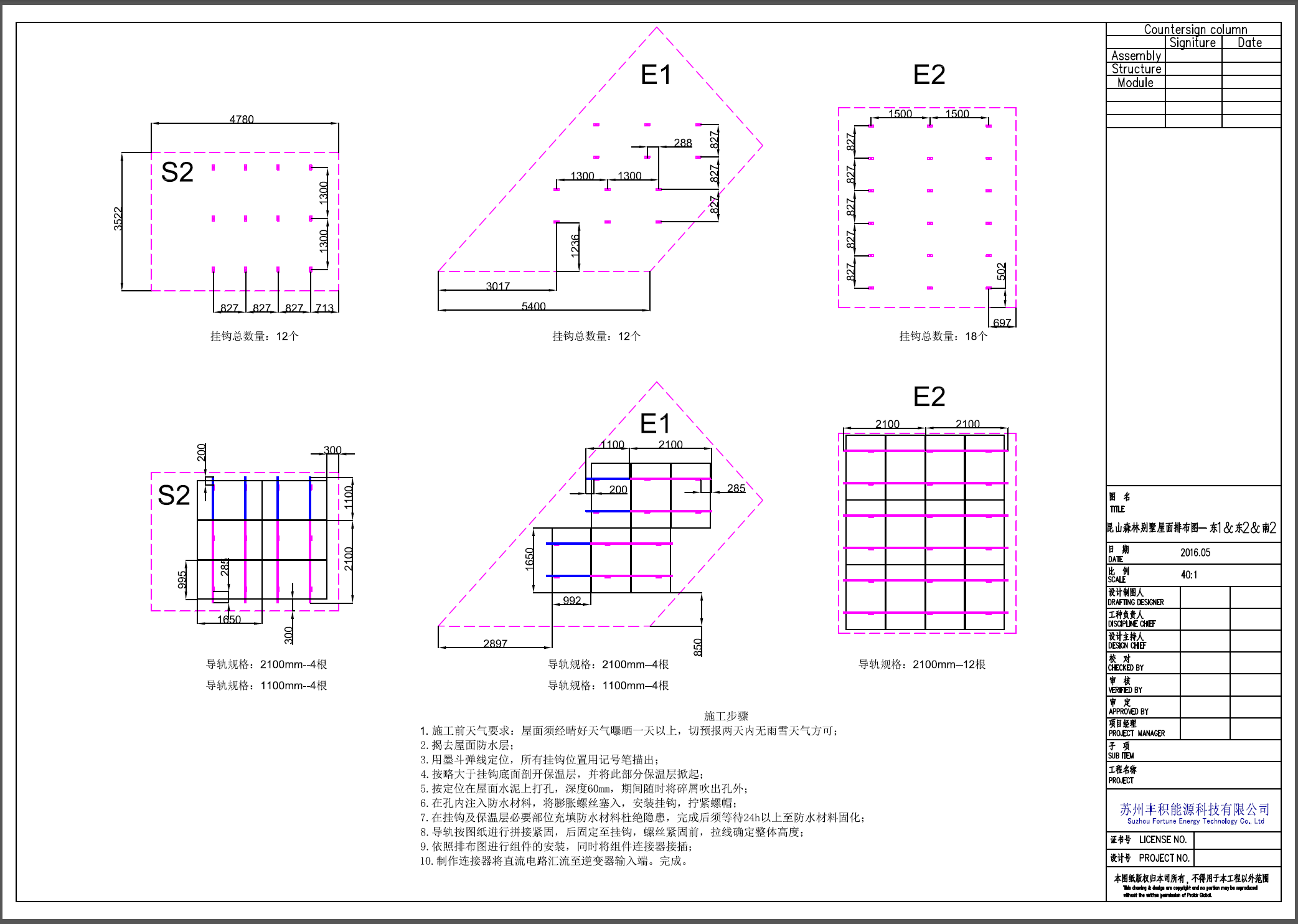

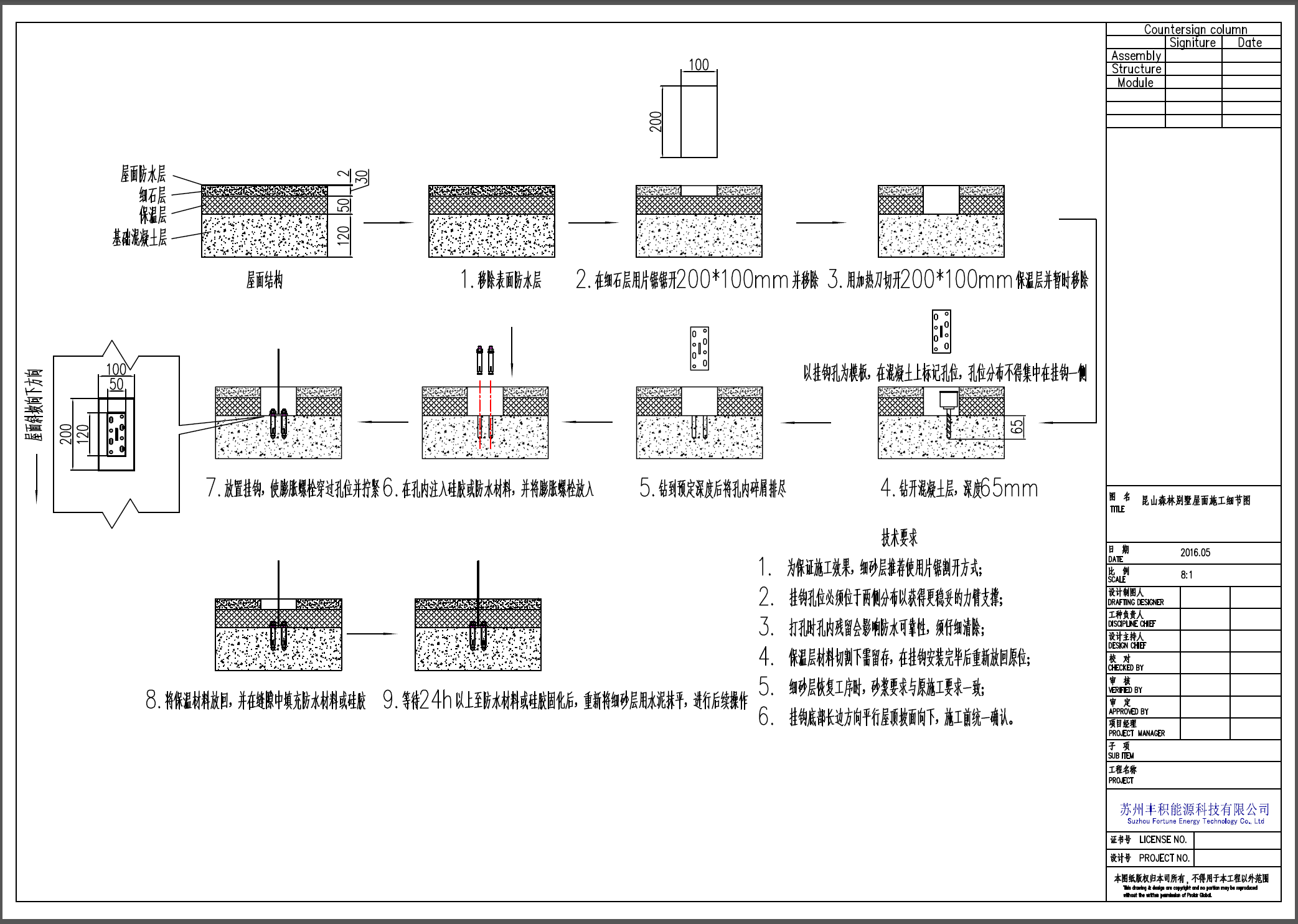

Installation Schematic Diagram

Power Plant Project Schedule

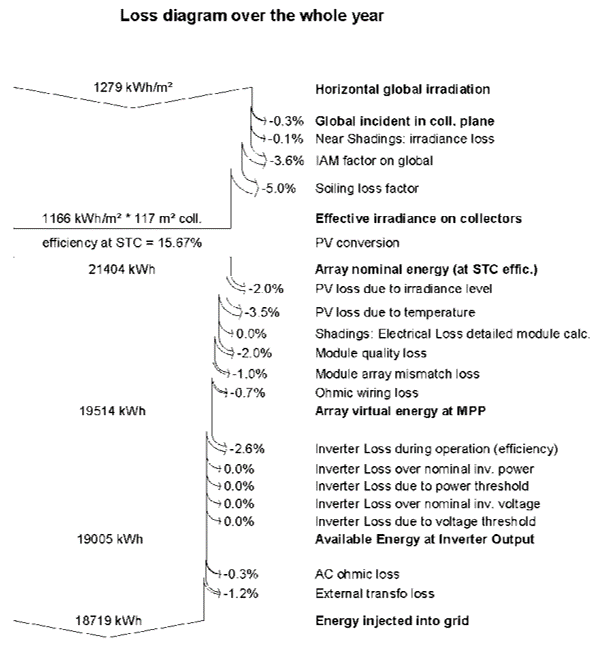

Power Plant Simulation Report

Design Report

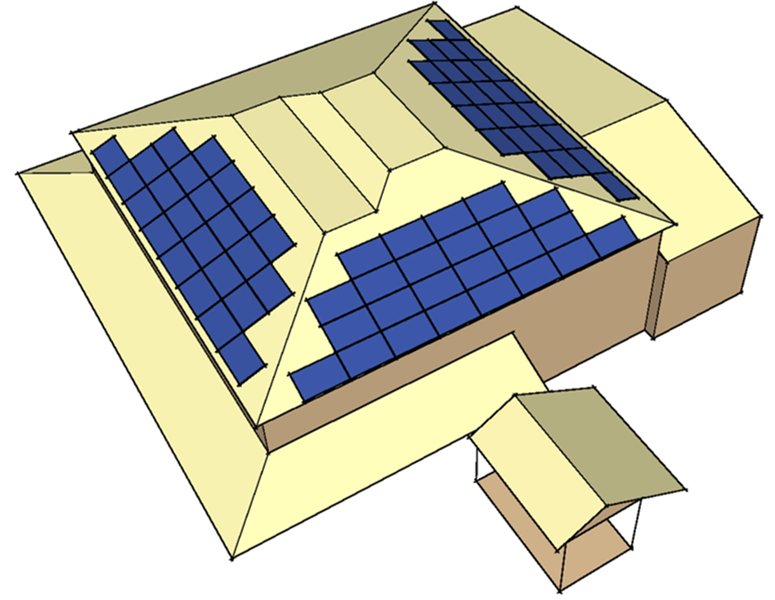

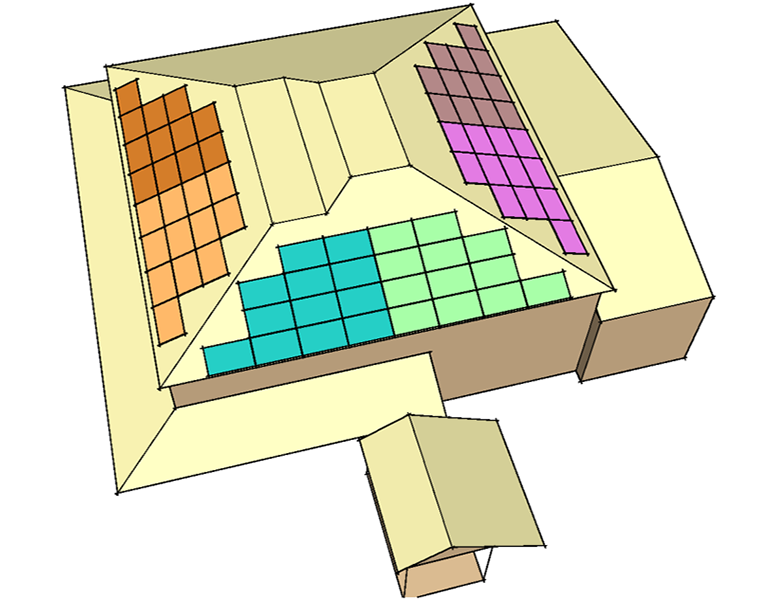

3D Modeling Layout

Electrical Connection Diagram

According to the simulation of shadow occlusion, the current and voltage adaption caused by occlusion are calculated, and then the whole system design are optimized. (modules in the same array are same color)

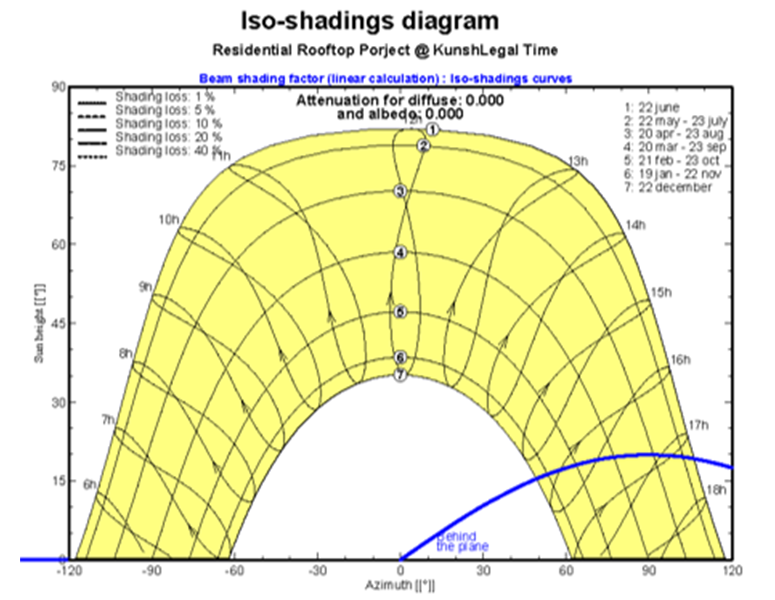

Shadow Analysis Chart

Combined with meteorological data, geographical conditions, loss parameters (shadow, dust, electricity), modules, inverters and other parameters, a more detailed power generation prediction is carried out.

PV PLANT O&M

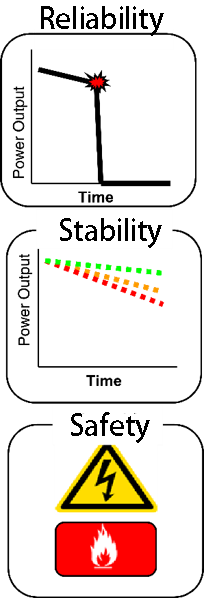

High efficiency and performance of the power station ensures safe, stable and reliable electricity revenue!

WHY NEED O&M?

It will be dangerous without professional O&M.

Maintenance contentS

1. Regular cleaning the modules, the surrounding environment; derusting the racking.

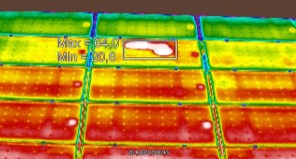

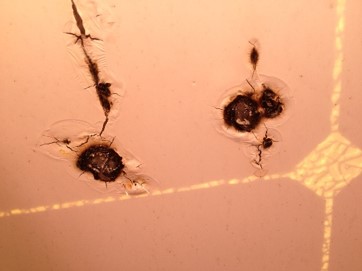

2. Aerial photography technology realizes efficient and accurate hot spot inspection; EL detection at power station side; terminal detection.

3. Detection of the inverter.

4. Maintenance of distribution cabinet.

No. | ITEM | No. | ITEM | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

1 | Hot spot detection | 2 | Stain cover loss | ||||||||

3 | Module performance degradation | 4 | Mismatch loss of module string | ||||||||

5 | MPPT deviation loss | 6 | Temp. loss of module string | ||||||||

7 | Microcrack check | 8 | DC cable loss | ||||||||

9 | Shielding loss between arrays | 10 | Inverter efficiency | ||||||||

11 | Inverter MPPT efficiency (optional) | 12 | Transformer efficiency | ||||||||

13 | AC cable loss | 14 | Power quality of connect points | ||||||||

15 | Power factor of connect points | 16 | Power generation efficiency | ||||||||

17 | Insulation of PV array | 18 | Ground connection test | ||||||||

19 | Anti islanding test (optional) | 20 | Low voltage ride through test (optional) | ||||||||